Description

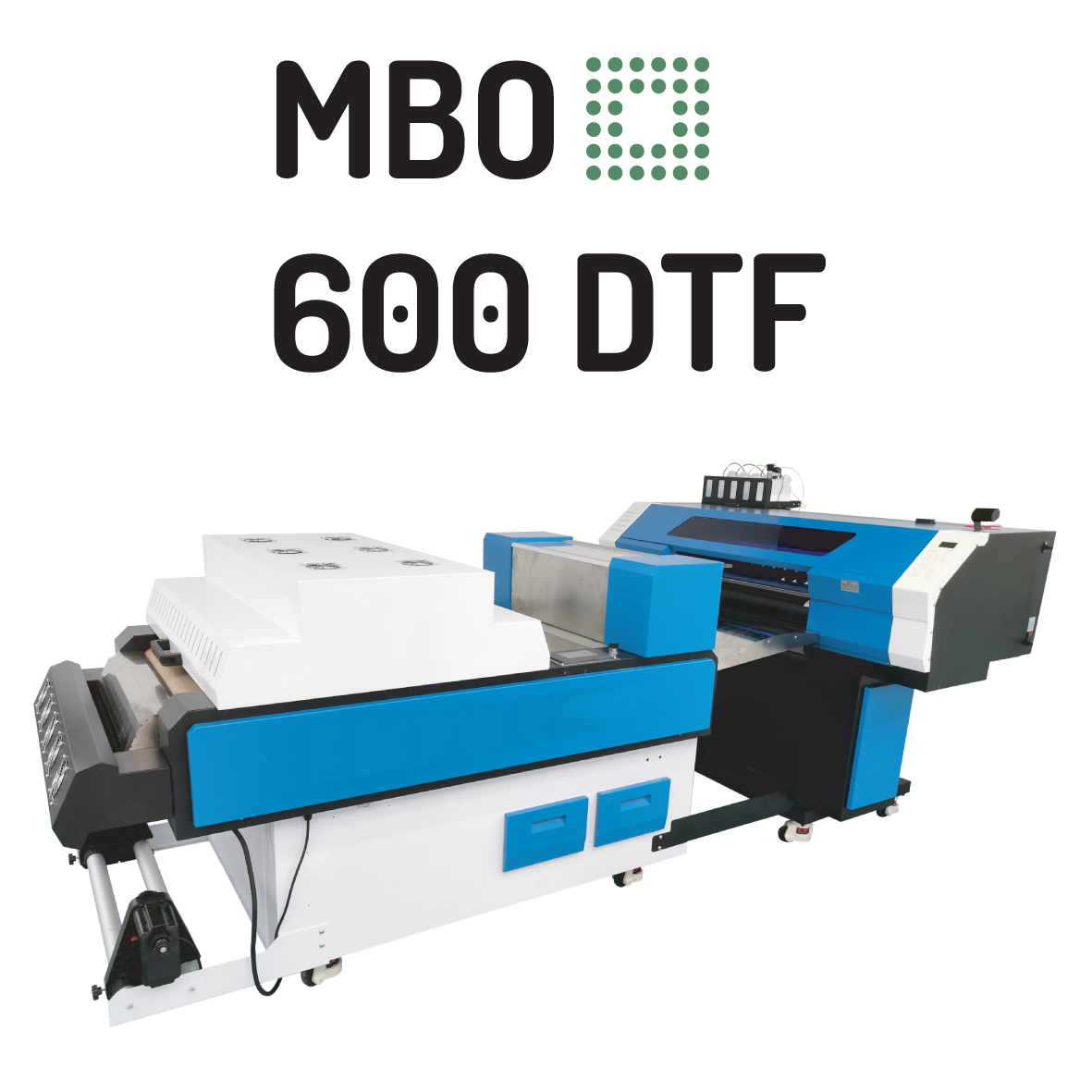

MBO 30-DTF

Definitive DTF integration

Feature

The MBO DTF-30 train has come to the customization market to stay. We can print several products and materials such as leather, polyester, cotton, nylon, wood, among others at a very low production cost.

This new printing technology allows us to print in four colors, without the need to create a color screen, as well as gradients with ease, maintaining a high production autonomy, without the need for an operator cuts or peels off the vinyl before applying it.

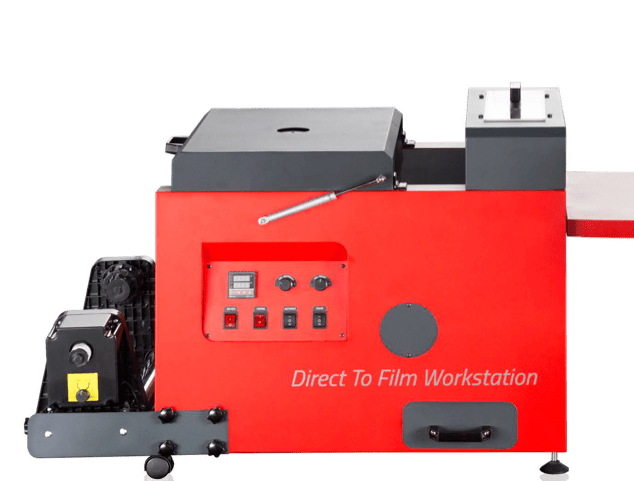

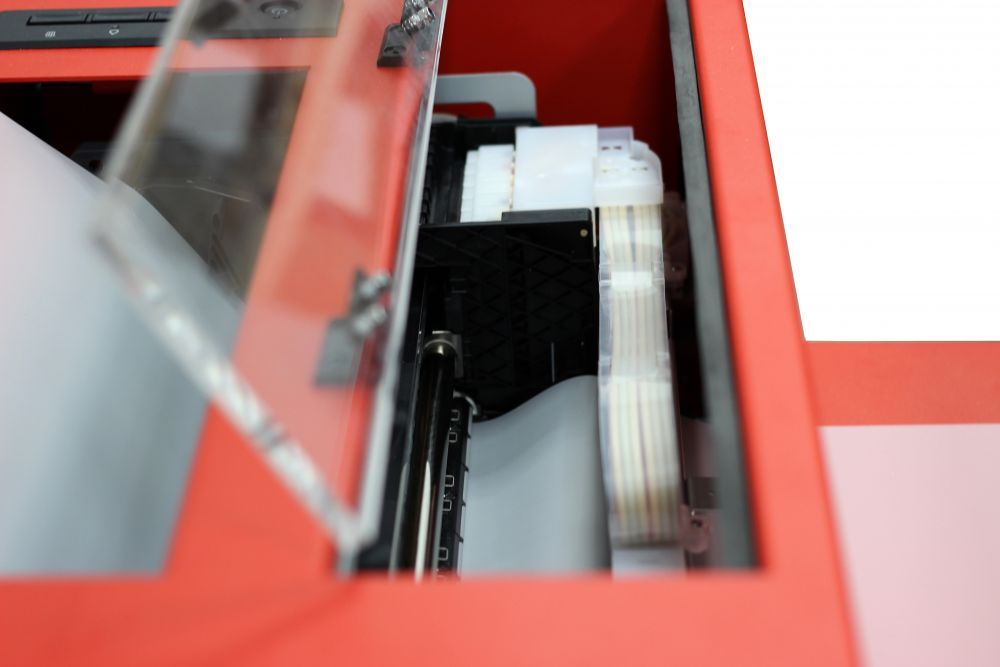

Non-stop printing and curing

The work train is composed of an unwinder, a printer with a width of 30 cm for the entry of the material and a drying oven with a rewinder. Thanks to the latter, we can easily apply the glue powder and harden the material before rewinding the printed material, with which we can print up to 100 linear meters without worrying about changing the unit sheets or applying the finish manually .

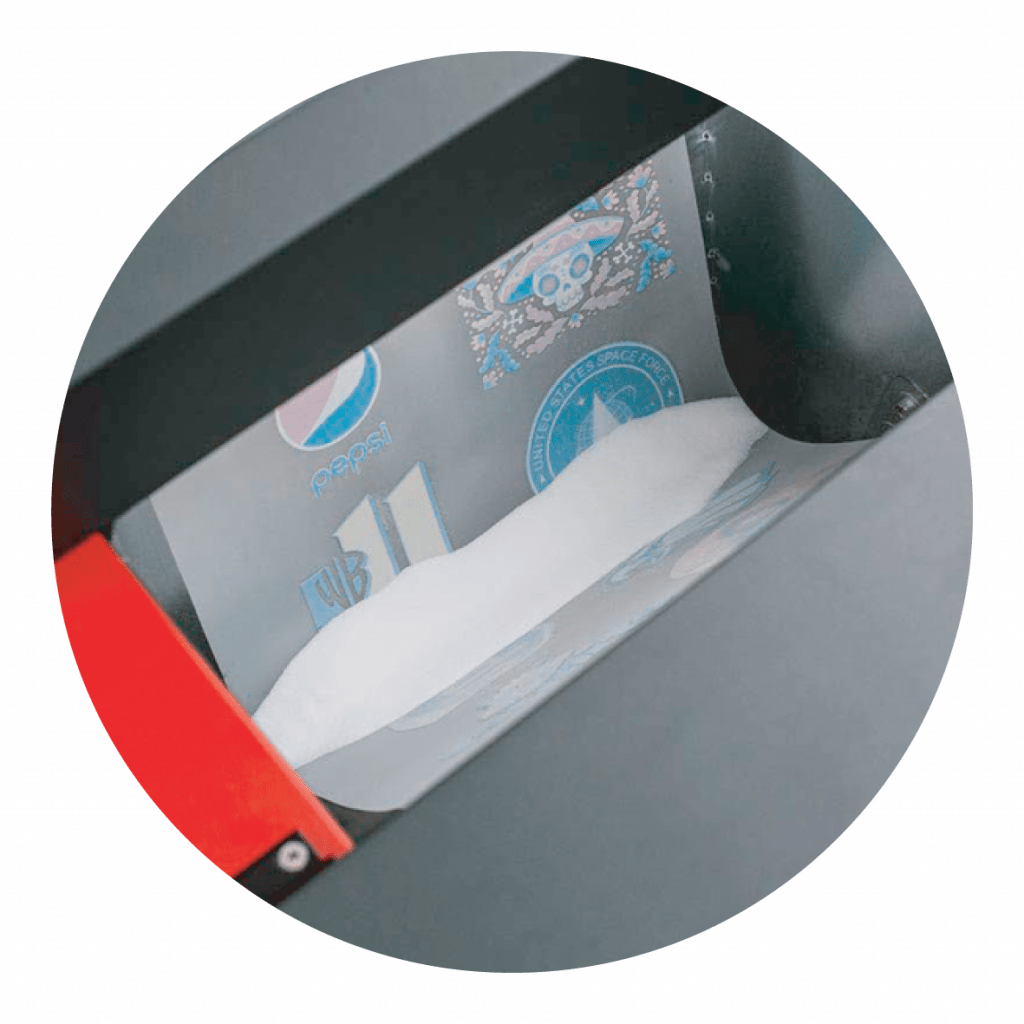

Adhesive application

Collection tray

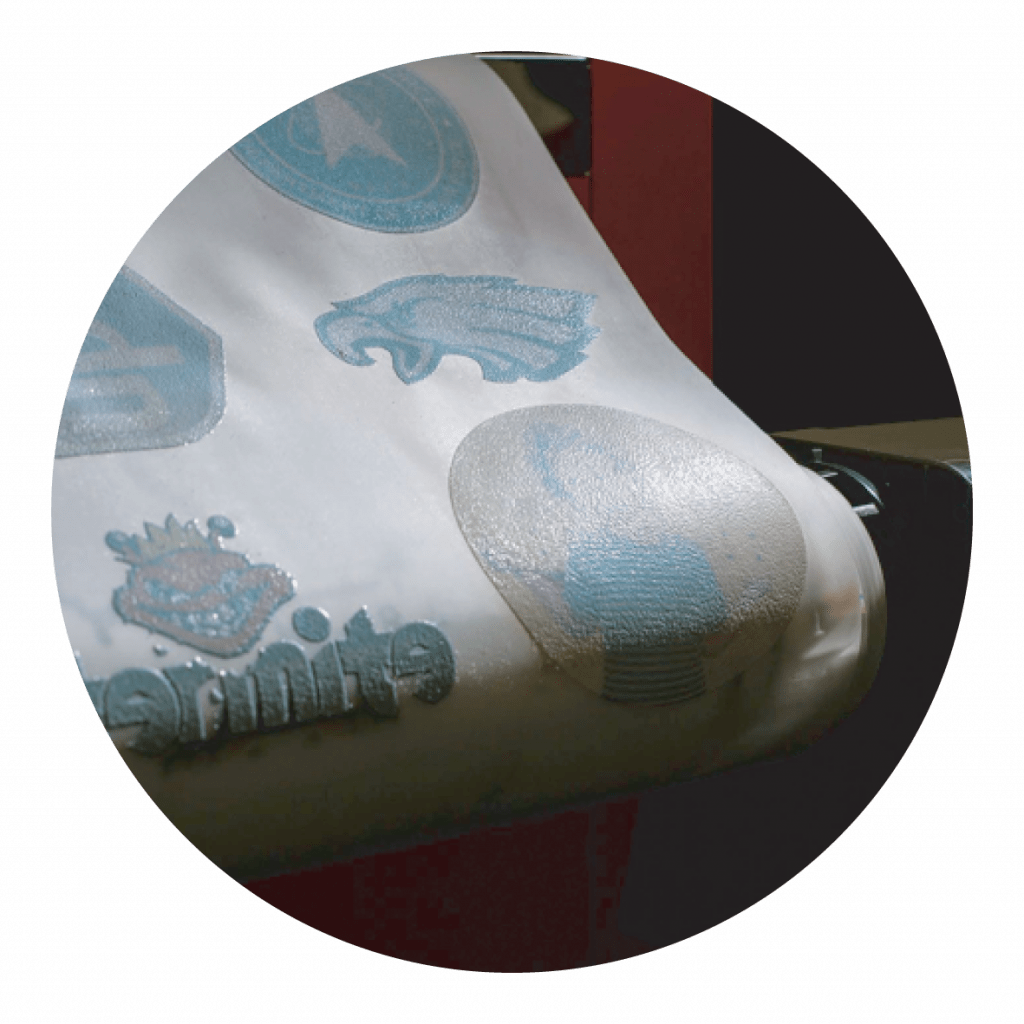

Film Texture

Curing system

Control Panel

Film Rewind

REQUEST A PRINT SAMPLE OR A PRODUCT DEMO

This pioneering printing system works in CMYK + WHITE, which allows us to apply the design to the surface in the color we want, without the need for prior stamping or printing processes.

Once the whole printing process has been done on the DTF film, it is ready to be applied to the desired part using a heat press or we can store it for later printing. After its application we will have a soft and extraordinarily elastic and resistant touch, allowing us to stretch the piece without creating a crack in the print.

Materials

The versatility of DTF transfer printing allows us to print both on porous materials such as wood or graphic cardboard and on different fabrics of any component and color.

Work process

Design Pattern

Use photoshop, illustrator or other software to design your pattern.

Print Your Design

Adjust the printer parameters in the RIP software and use our printer and ink to print your pattern.

Powdering

Turn on the switch of the powder shaking machine, the machine will automatically powdering, and dry and fix the color.

Heat Press

Use a heat press machine, set the temperature to 180 degrees, and time 15 seconds to transfer.

MBO 30-DTF Parameters

| Print area | 290 mm x 100 m |

| Print speed | 720 x 720 dpi – 7 linear metres per hour 1440 x 720 dpi – 1.8 linear metres per hour |

| Support width | 30 mm |

| Roll outside diameter | 135 mm |

| Number of inks | CMYK + WHITE |

| Inkwell capacity | 250 ml |

| Consumption | 1500 W |

| Connectivity | USB 2.0 |

| Curing oven | Including |

| Types of compatible materials | Wood, graphic cardboard, cotton, linen, leather, wadding, polyester, nylon. |

| Net weight and dimensions | 150KG 1800 mm x 800 mm x 600mm |

| Weight and packaging dimensions | 250KG 1200 mm x 800 mm x 1000mm |

| Software | Digital Factory V10 |