Description

MBO 600 DTF Pro Film Printing Machine

Direct to Film Comprehensive Solution

Model:MBO 600 DTF Pro

Parameter

- Print Head: Dual Epson PrecisionCore™ I3200/4720 print heads.

- Max Print Size: 600mm Print Width.

Feature

MBO 600 DTF is a new generation of the digital revolution, creating a new digital dtf film printing process. It makes up for the shortcomings of the existing dtf technology. The max print width 24inch. Using Epson Print head, incbuding 400 nozles/rowv*g*lincs*2, high quality up to 1800dpi

REQUEST PRINT SAMPLE OR PRODUCT DEMO

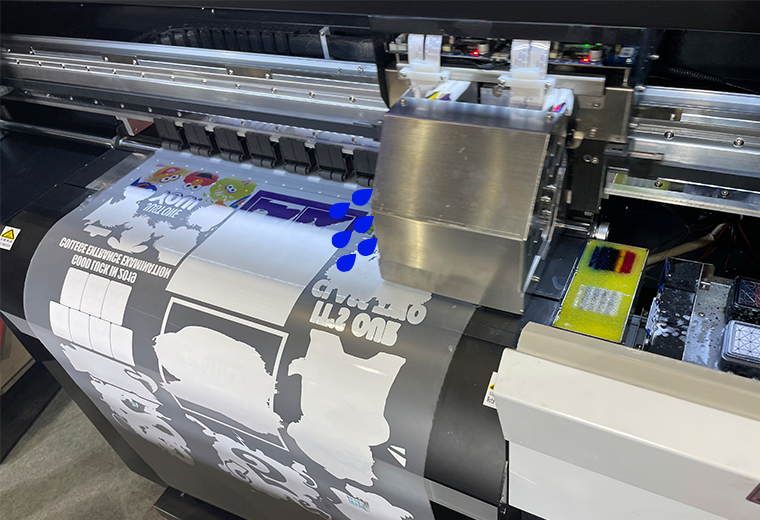

Staggered inkjet printing technology

The new generation of dual-nozzle staggered printing technology greatly improves the printing speed, 4pass accuracy surpasses 6pass

Suction System Upgrade

Vacuum adsorption conveying platform, absorbing the print material to ensure that the material does not bulge or run off.

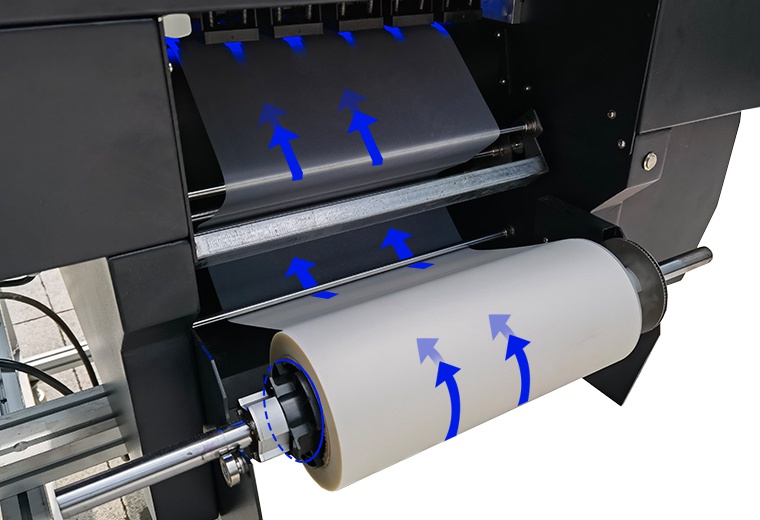

Constant Tension Control System

Tension control system automatically controls tension during DTF flm printing processes.

Powder Box Upgrade

Conical powder box, reduce the burden on the motor and extend the life of the motor.

Epson I3200-A1/4720 Print Head

MBO 600 DTF using Epson I3200 print heads. Epson I3200 head has 3200 nozzles, resolution 600npi, jetting frequency are higher than DX5 and xp600, and also color saturation, printing speed, printing accuracy are better, and the price is cheap. Very cost-effective

| Model | I3200-A1/4720 |

| Ink Types | Water based ink |

| Size(width x depth x height)(mm) | 69.1×59.4×35.6 |

| Weight(g) | 82 |

| Nozzle Numbers | 3200 |

| Length Between Nozzles(inch) | 1/300(in one row) |

| Nozzle Row | 8row |

| Max color/head | 4colors |

| Resolution | 300npi/1row 600npi/2row |

| Effective Printing Width(mm) | 33.8 |

| Jet Freqency(kHz) | 43.2(single dot), 21.6(multi dot) |

| Ink Drops(pl) | 3.8-6-12(9.4) |

| Ink Viscosity(mPa.s) | 3~4 |

Working Process

Design Pattern

Use photoshop, illustrator or other software to design your pattern.

Print Your Design

Adjust the printer parameters in the RIP software and use our printer and ink to print your pattern.

Powdering

Turn on the switch of the powder shaking machine, the machine will automatically powdering, and dry and fix the color.

Heat Press

Use a heat press machine, set the temperature to 180 degrees, and time 15 seconds to transfer.

Advantages of MBO DTF printers

MBO DTF Printers have upgraded the nozzle printing algorithm, suction system, tension system, and shaking powder system. Which improves the stability of the machine, prolongs the service life of machine parts, and makes the machine more efficient.

- The next generation oblique spray staggered inkjet printing, improved the printing speed, 4pass accuracy surpasses 6pass.

- During the printing process, the tension system prevents the print medium from stretching or shrinking, causing sudden registration errors.

- The front and rear suction system facilitates the pass through of the printing film and makes it very easy to cut a section of the sample during the printing process.

- The cone-shaped powder box not only saves dtf powder, but also disperses the heat of the machine at work, and extends the life of the motor

- Active ink supply system and onstant pressure ink system.

Machine Parameter

| Item Model | MBO 600 DTF | |

|---|---|---|

| Print Head | Using Epson Print head, including 400 nozles/rowv*g*lincs*2, high quality up to 1800dpi | |

| Print Resolution/Speed | 4pass:10m2 -15m2 /hour 4pass:22m2 -34m2/hour | |

| 6pass:6.5m2-10m2/hour 6pass:16m2 -24m2 /hour | ||

| 8pass:3.5m2 -6m2/hour 8pass:12m2 -16m2/hour | ||

| Ink | Sort | DYE DYEYR RZY |

| Capacity | 5 Colors : 1.5L*5/color | |

| Media | Maximum width | 620mm |

| Thickness | 1.5mm to 6mm adjustable | |

| Max Roll Weight | 20KG | |

| Sort | PP Sythentic paper, vinyl sheet, film, coated paper, Acid Proofpaper bamer, canvas ,etc. Adhesive Vinyl sheet, Banner and so on | |

| High Printing | Three inteligent eclosion paint functionVSD technology | |

| Madia Heater | PrePost Heater (Can be controlled separately) | |

| Interface | USB 2.0 | |

| RIP Sofvare | Maimop6.0, Photoprint, Print Factory | |

| Powder | AC110V+/- 10%、AC220V+/-10%、 50/60+/HZ | |

| Operation Enviroameats | Temperature20℃- 35℃、Humidiry35%RH-65%RH | |

| Powder | Printing 200W, heating 450W before/middle/after | |

| Dimensions | 1785*790*1613mm (L*W*H) | |

| Height of Worktable | 1062mm | |

| Package size | 1880*970*740mm (L*W*H) | |

| Net Weighs | 180KG | |

| Gross Weight | 200KG |