Discover the revolution of textile customization

DTF Printing Systems

DTF Printing is also referred to as Direct To Film Printing, and it works by printing transfers that are heat pressed to a variety of garments (and other substrates).

When you have this machine, you can print on any kind of fabric, no matter dark or light.

There can be more varieties in your product line. Save labor costs, and one employee can operate the machine.

Faster production can print 900+ sq feet in a day.

New Generation MBO DTF PET Film Printing Machine with Powder Shaking integrates vinyl powder coating and drying into one machine. When the film/vinyl is dried out, it can be used to transfer print onto the garment.

Which cab to be press on both dark and light Garments like cotton, polyester, 50/50 blends, spandex, leather, nylon and more.

Working Process

Design Pattern

Use photoshop, illustrator or other software to design your pattern.

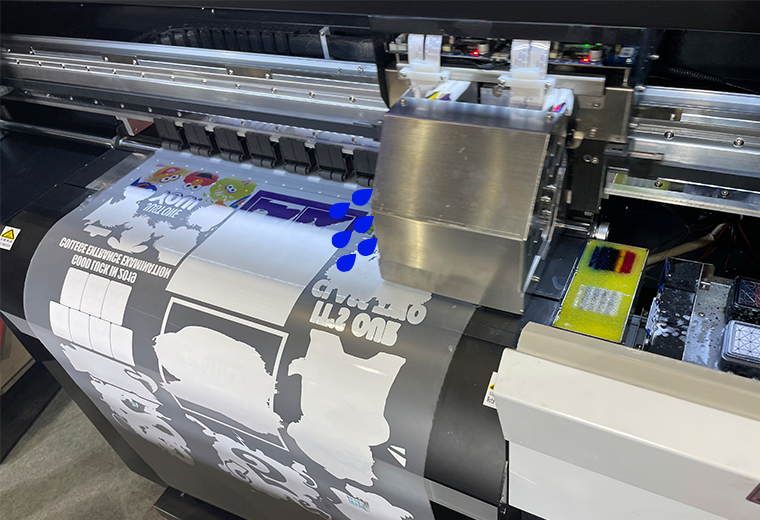

Print Your Design

Adjust the printer parameters in the RIP software and use our printer and ink to print your pattern.

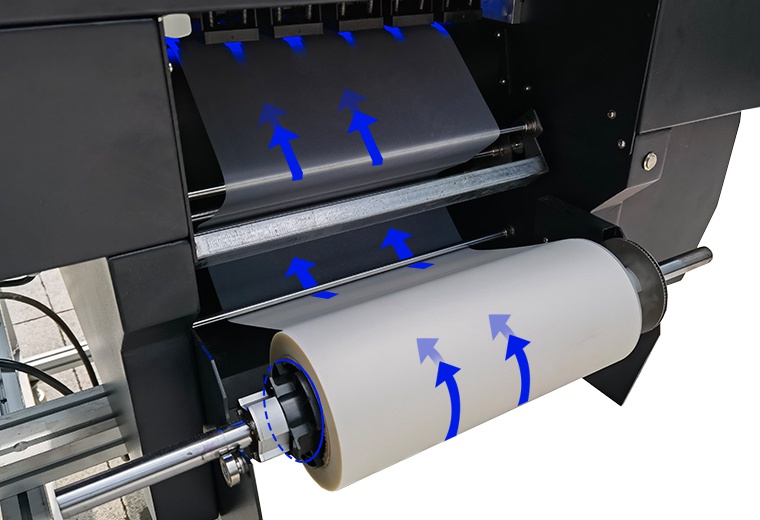

Powdering

Turn on the switch of the powder shaking machine, the machine will automatically powdering, and dry and fix the color.

Heat Press

Use a heat press machine, set the temperature to 180 degrees, and time 15 seconds to transfer.

Advantages of MBO DTF printers

MBO DTF Printers have upgraded the nozzle printing algorithm, suction system, tension system, and shaking powder system. Which improves the stability of the machine, prolongs the service life of machine parts, and makes the machine more efficient.

- The next generation oblique spray staggered inkjet printing, improved the printing speed, 4pass accuracy surpasses 6pass.

- During the printing process, the tension system prevents the print medium from stretching or shrinking, causing sudden registration errors.

- The front and rear suction system facilitates the pass through of the printing film and makes it very easy to cut a section of the sample during the printing process.

- The cone-shaped powder box not only saves dtf powder, but also disperses the heat of the machine at work, and extends the life of the motor

- Active ink supply system and constant pressure ink system.